During the rainy season or in humid climates, how should the heat transfer materials be stored?

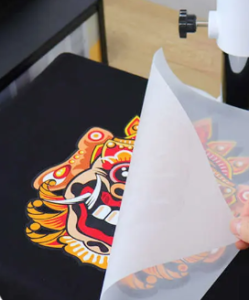

When producing heat transfer films, factories are paying extra attention to the production environment. That is, temperature and humidity. This has a significant impact on the quality of the Heat Transfer film. When making heat transfer films, the glue and ink can change color due to humidity. Ultimately, the accurate color requirement cannot be achieved.

That is, temperature and humidity. This has a significant impact on the quality of the Heat Transfer film. When making heat transfer films, the glue and ink can change color due to humidity. Ultimately, the accurate color requirement cannot be achieved.

Therefore, the production process needs to be strictly controlled at each step. Storage temperature: about 25°. Meanwhile, unused products are recommended to be packed well in PP bags, placed neatly and kept ventilated indoors. Not only should we pay attention to the storage of heat transfer materials, but we also need to pay attention to the equipment. Heat transfer machine moisture will affect the effect of ironing.

Thus, in wet weather using the heat transfer machine, we can fully preheat and remove moisture before use.If materials and machines are impacted by moisture, during heating, chemical reactions occur and gases are produced and bubbles appear in the end result.